TS55-1800

Mimaki TS55-1800 dye-sublimation transfer inkjet printer

The TS55-1800 is a dye-sublimation transfer paper model, offering new levels of quality and productivity for digital textile printing. This printer keeps running costs low with the mini jumbo roll and 10 kg ink supply units, which allow for unattended continuous printing. A maximum output of up to 1,506 SqFt/Hr can be achieved in four-color mode. New Sb610 inks, with fluorescent yellow and pink, provide enhanced resolvability to improve print production yields.

Benefits of the Mimaki TS55-1800

- Dedicated transfer paper printer – Mimaki Vision Jet-X

- Includes technologies for printing onto thin transfer media without cockling interference

- 76.3-inch (1,940 mm) print width

- New Sb610 dye-sublimation inks with improved stability; Available with fluorescent inks

- Optional units – Mini Jumbo Roll, 10 kg Ink Supply and Extended Heater

- Run high-speed with MAPS for smooth images

- Nozzle Check Unit and Nozzle Recovery System

- Advanced TxLink4 Lite RIP Software is available as an option

Maximum Output Speed of 1,506 SqFt/Hr (140 SqM/Hr)

Incorporates various print modes suitable for any workflow, ranging from a high-speed print with a maximum rate of 1,506 Sqft/Hr (140 SqM/Hr) to practical quality print with an output speed of 592 SqFt/Hr (55 SqM/Hr) and finally, quality-oriented print speed of 333 SqFt/Hr (31 SqM/Hr). The practical quality mode achieves approximately 140 percent (*1) higher productivity in comparison with our conventional model, TS300P-1800.*1- Comparison using TS55-1800: 600×600 dpi, 2 pass and TS300P-1800: 720×720 dpi, 4 pass, Hi (in the practical quality mode)

Optional Units Achieve Low Running Costs and Continuous Operation

Mini Jumbo Roll Unit

- This is a feeding unit to load Mimaki Vision Jet-X transfer paper with a length of about 8,202 feet. It reduces the cost per square foot and shortens the downtime due to media replacement in comparison to smaller transfer paper rolls.

10 kg Ink Supply Unit

- This is an ink supply unit to set a 10 kg (22 lbs.) ink tank for a single color. Compared with the conventional 2 liter ink pack, the running cost is greatly reduced and the downtime due to ink replacement is shortened.

Extended Heater

- This extended heater is installed to the lower part of the standard heater. The heater enhances the ink-drying capability and prevents the blocking of media caused by wet ink obstructing the feed during high-speed print, therefore ensuring a stable production.

Newly Developed Printheads Ensure High-Quality Prints (Even at a High Speed)

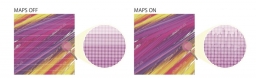

The Mimaki Advanced Pass System (MAPS) provides gradation to printed pass boundaries to maintain a stable print quality by reducing banding and uneven color. The TS55-1800 is equipped with newly developed printheads that enables MAPS in the high-speed mode. This technology allows the simultaneous pursuit of both high speed and quality.

Technologies for Uninterrupted Reliable Printing Operation

Mimaki’s unique automatic Nozzle Check Unit (NCU) is mounted. When the NCU detects a missing nozzle, it automatically performs cleaning to solve the problem. When the missing nozzle is still unsolved even after the cleaning, the Nozzle Recovery System (NRS) is used to continue printing by switching to another nozzle. The print can be restarted to maintain productivity, without the need to wait for a service representative.

Advanced TxLink4 Lite RIP Software

- A 16-bit rendering creates beautiful gradation expression.

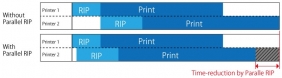

- Parallel RIP and load balancing functions make production more efficient.

The RIP process for multiple pieces of print data can be performed in parallel. In addition, the load balancing function enables print jobs to be assigned to vacant printers automatically, allowing efficient production when multiple printers are connected (*2, 3).

*2- Identical printers / identical ink-set printers

*3- Additional printer licenses corresponding to the number of connected printers are required.

Parallel RIP function

RIP processes can be performed in parallel, making production that uses multiple printers (*2, 3) efficient. The parallel processing capability can handle up to eight jobs.

Load balancing function

Print jobs are pooled and automatically assigned to multiple printers (*2, 3).

- Variable print function tailored to applications for apparel is provided.

Variable data, such as uniform numbers and player names, can be directly imported from a CSV file to create multiple print jobs. The text can also be processed using methods, such as text outline fills and arched text layout.

Spot Color Inks Enable Beautiful and Unique Expression

- Light black ink creates stunning gray-scale expression

- Because sublimation transfer print uses a high-density black ink, graininess or tone jump may occur in some cases. Light black ink allows for smooth printing without graininess or tone jump.

- Fluorescent inks creates unique expression

- The demand for fluorescent inks is rising in products, such as uniforms and other sports apparel, fashion apparel, and eye-catching bright soft signage. To use fluorescent inks as the complementary colors of process colors, not to mention as spot colors, a multi-color mode (*4) is provided. The fluorescent inks complement magenta and yellow to create brighter colors.

*4- Only available in TxLink4

Mimaki Vision Jet-X Allows for Longer Production Runs

Mimaki Vision Jet-X jumbo rolls has approximately 8,202 feet of transfer paper. When running the TS55-1800 printer at its maximum speed (1,506 SqFt/Hr; 140 SqM/Hr), a 492-foot roll of transfer paper runs out in approximately two hours. The system was therefore incapable of coping with an uninterrupted operation, such as overnight printing in the absence of operators. The Mimaki Vision Jet-X jumbo roll allows for unattended printing with a longer production run. The mini jumbo roll also contributes to reducing the running cost with lower paper costs per square foot in comparison to normal plotter roll.

What you can do with the Mimaki TS55-1800 Printer

With dye-sublimation inks:

- Performance apparel

- Fashion textiles

- Soft Signage

- Backlit fabric signage

- Exhibit graphics

- Banner

- Flags

- Interior Décor

- and more…